Air Injection Transparent Png Cavitation

As a result.

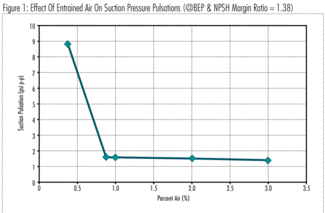

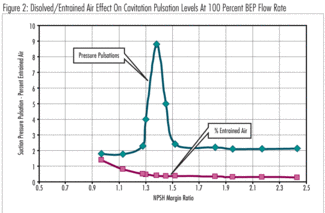

Air injection transparent png cavitation. The corresponding injection pressure varied from 1 105 pa to 12 10 5 pa which is sufficiently high to introduce strong cavitation in large nozzle. The air injection rate is controlled by using a programmable variable speed syringe pump new era pump system inc just infusion pump ne 300. Pressurized air injection in an axial hydro turbine model for the mitigation of tip leakage cavitation a rivetti 1 m angulo c lucino1 and s liscia unlp laboratory of hydromechanics 47 street. By the air injection ring.

When investigating the dynamics of cavitation vapor bubbles in the transparent nozzle the ambient condition is atmospheric. 320 128 pixels frame. Abstract it has been pointed out that cavitation occurs in a nozzle of a fuel injector for a diesel engine and affects the injected spray. One was photron fastcam sa1 1 resolution.

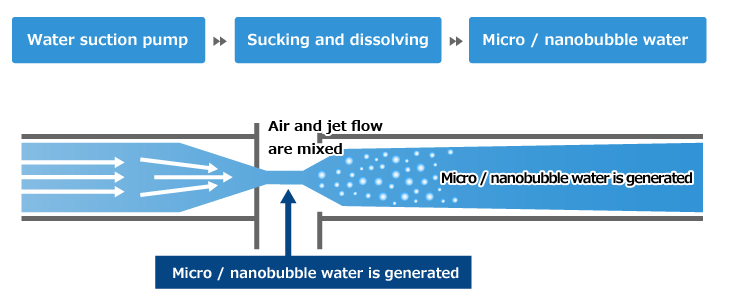

In the nozzle a so called string cavitation which. To answer these unknown questions a visual injection system with a 5 time scaled up transparent nozzle is built and high speed imaging technique is first used to study the characteristics of cavitation under various injection pressures and needle lifts in the present study. Cavitation behavior during fuel injection8. In order to continuously inject air bubbles into the water stream a solid rod with a 1 mm deep groove is.

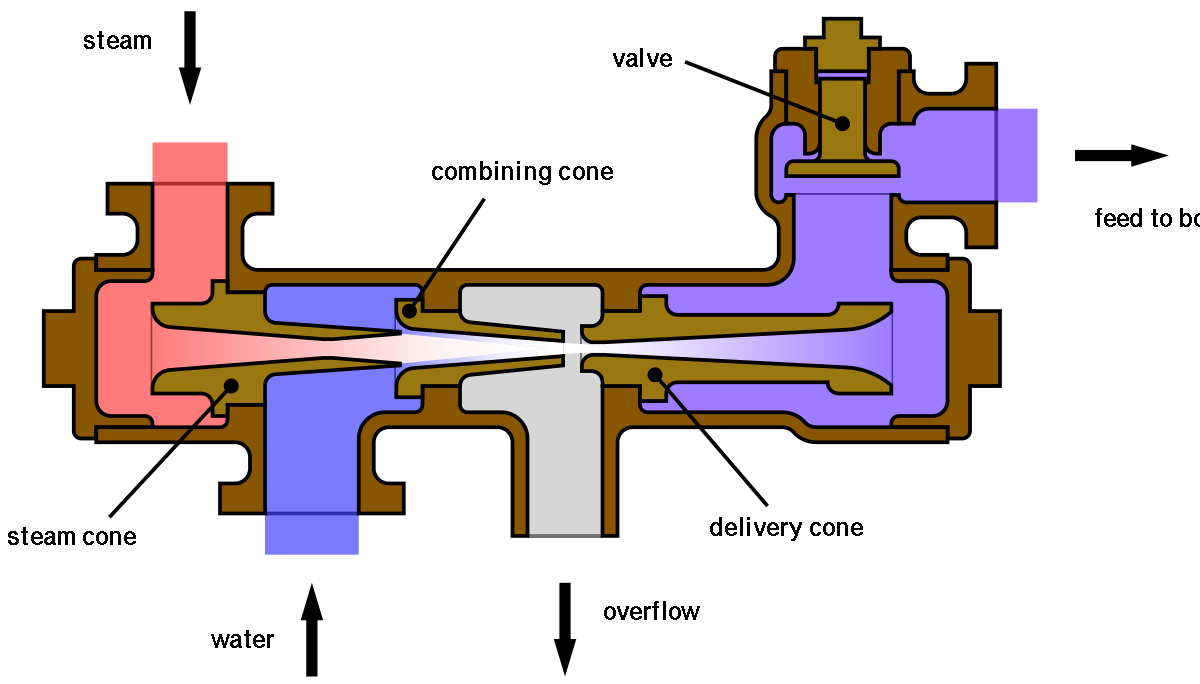

A shadowgraph technique was introduced to observe cavitation in the nozzle and the spray formation process during fuel injection. The transparent symmetrical venturi nozzle is placed in the test section see. Cavitation and aerated cavitation experiments has been carried out on a symmetrical. The needle lift is controlled to achieve various throttling strengths.

At the injection pressure of 100 mpa the reynolds number of the in nozzle flow was on the order of 10 4 and the flow was in the lamellar to turbulent transition region if confined in a pipe. Two types of high speed camera were used for visualization. For injection into air due to the small depth of field of the optics and due to the difference in optical path between for the light going through the transparent nozzle and the light traversing. The syringe pump is connected to the top of the test section with a flexible transparent tube i d.